PRODUCT DETAILS

Product Overview

This machine is suitable for various chairs with armrests, such as office chairs and gaming chairs. Generally, the office chair is fixed on the testing platform, and mechanical devices such as pneumatic cylinders, hydraulic cylinders, or electric actuators are used to apply forces of different directions and magnitudes to the armrests. It simulates various actions of a person using the armrests of the chair, such as pressing, pushing, pulling, and leaning. The machine is equipped with corresponding sensors and control systems to accurately measure and record parameters such as deformation, displacement, and force experienced by the armrests during the testing process.

Product Application:

This machine is suitable for various chairs with armrests, such as office chairs and gaming chairs. Typically, the office chair is fixed on the testing platform, and mechanical devices like pneumatic cylinders, hydraulic cylinders, or electric actuators are used to apply forces in different directions and magnitudes on the armrests. It simulates real-life usage scenarios, including pressing, pushing, pulling, and leaning. Equipped with sensors and a control system, it accurately measures and records parameters such as deformation, displacement, and force applied to the armrests during testing.

Product Features:

-

Realistic Simulation of Usage Scenarios:

- Simulates various force applications and usage frequencies that armrests experience during actual use, providing results that better reflect the true performance of the armrests.

-

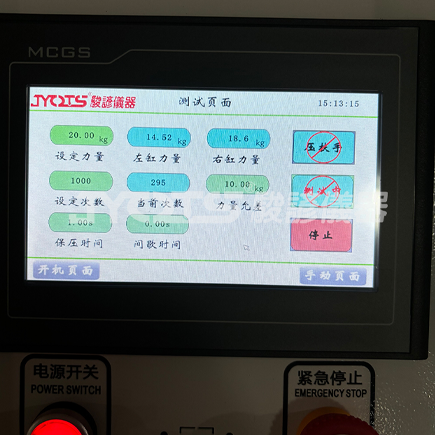

Adjustable Parameters:

- Allows flexible adjustment of key parameters such as force magnitude, loading speed, cycle count, and testing angle to meet diverse testing requirements for various office chair armrests.

-

Accurate Data Recording and Analysis:

- Records various data in real-time with high precision and processes it using specialized software.

- Generates detailed test reports and charts, providing valuable insights for evaluating armrest performance, identifying potential issues, and improving product design.

-

High Level of Automation:

- Features automated loading, control, data collection, and processing functions, reducing manual intervention.

- Enhances testing efficiency, accuracy, and minimizes human error.

Compliance Standards:

- ANSI/BIFMA X5.1-2017 12 Arm Strength Test - Vertical - Static

Technical Parameters

Technical Specifications:

-

Control Method:

- Computer-controlled with real-time curve display.

-

Electric Cylinder:

- Stroke: 400mm

- Movable laterally with an adjustable angle from 0–10°.

-

Crossbeam:

- Adjustable up and down to control the test arm, ensuring compliance with the standard length of 600±10mm.

-

Force Sensor:

- Capacity: 200kgf

- Resolution: 1/100,000

-

Dynamic Force Accuracy:

- ≤±1% (exceeds BIFMA/EN tolerance standards for test forces between 400–1125N).

- Electric cylinder recommended over pneumatic systems for higher precision and minimal force deviations.

-

Transmission Method:

- Servo electric cylinder transmission for stable and precise operation.

-

Machine Weight:

- Approximately 350kg

-

Power Supply:

- ∮ AC 220V 50Hz 5A