PRODUCT DETAILS

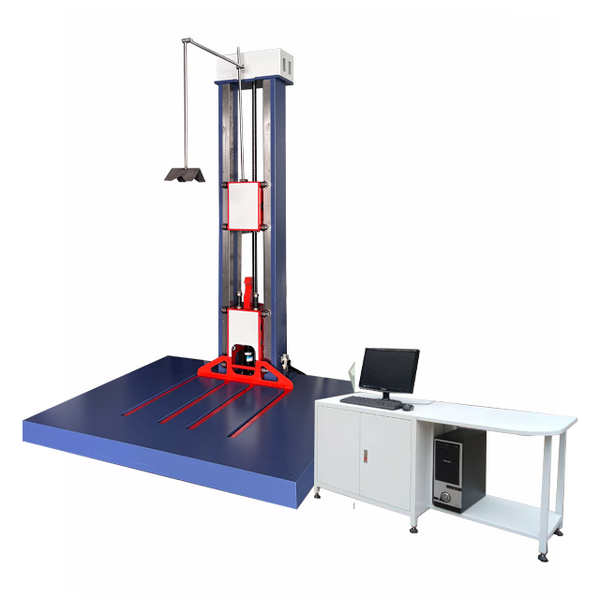

Zero Drop Impact Test Machine

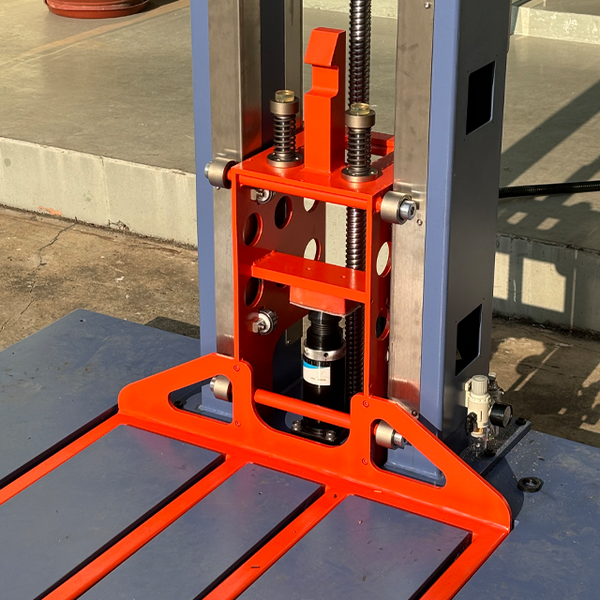

This test bench is mainly used to assess the package during the actual transport, loading and unloading process by the impact of the impact of drop to assess the packaging process in the handling of impact strength and packaging design of the rationality of zero drop test machine is mainly used for larger packaging drop test The zero drop tester consists of an "E" type fork that can move rapidly downwards as the specimen holder. The goods to be tested are balanced according to the test requirements (face, edge and angle experiments). During the test, the pallet moves downward at a high speed and departs from the test piece.

Application Mainly for large furniture (furniture), large-scale household appliances such as LCD TVs, air conditioners, washing machines, refrigerators and other products packaging zero drop test.

Design standard Zero drop impact tester complied with national standards such as GB/T1019-2008.

Control principle

The use of imported computer electrical design, complete free fall, edge, angle, face all aspects of design

The main technical parameters are as follows

|

Drop Height

|

150~1500mm (Adjustable)

|

|

Machine Dimensions

|

2200*1700*2300mm

|

|

Max. Specimen Weight

|

100kg

|

|

Height Display

|

LED digital display, and can be set to stop the height function

|

|

Impact Plate Material

|

45 # steel, (120 mm thick)

|

|

Drop Height Mark

|

Use markings scale

|

|

Arm Structure

|

45 # steel, welded by the side

|

|

Test method

|

Ling, angle, surface

|

|

Transmission

|

Taiwan imported linear slider and copper guide, 45 # chrome steel

|

|

Accelerator

|

Pneumatic

|

|

Max Size of Specimen

|

1000*1000*1000mm

|

|

Drop Method

|

Integrated with electromagnetic and pneumatic

|

|

Drive Mode

|

Motor drive

|

|

Protection Devices

|

Above and below are inductive protection devices

|

|

Net Weight

|

3000KG

|

|

Impact Countertops:

|

Steel

|

|

Voltage

|

3 phase 380V 50Hz ,5KW

|