PRODUCT DETAILS

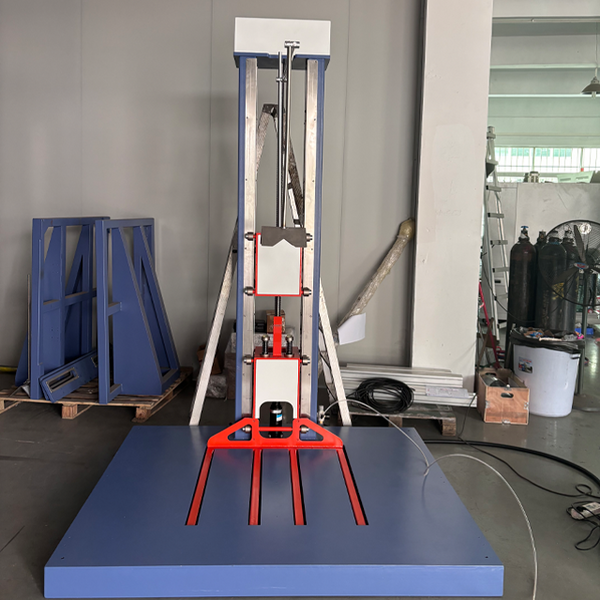

Zero Drop Tester – Validate Packaging & Product Durability Under Instant Impact

Simulate Real-World Drops from Zero Height for Critical Quality Assurance

Our Zero Drop Tester is engineered to evaluate product resilience and packaging integrity under sudden zero-height drops, replicating mishandling during logistics or assembly. Ideal for electronics, medical devices, and fragile goods, this tester ensures compliance with ISTA 1A, ASTM D5276, and MIL-STD-810G standards.

Core Features & Technical Precision

💥 Instant Impact Simulation

- Drop Height: 0 mm (zero-height release) to 1.2 m (adjustable for multi-height testing).

- Impact Velocity: Up to 4.4 m/s (controlled via electromagnetic release mechanism).

- Repeatability: ±1% impact energy consistency across 1,000+ cycles.

📦 Versatile Testing Modes

- Free Fall: Test package integrity with guided vertical drops.

- Edge/Corner Drops: Target specific product weak points with angle-adjustable platforms.

- Multi-Axis Testing: Perform face, edge, and corner drops in a single setup.

📊 Smart Control & Data Analysis

- 7-inch touchscreen with preset ISTA, ASTM, and custom test profiles.

- Real-time G-force measurement (up to 500G) via integrated accelerometer.

- Data export via USB/Bluetooth for failure analysis (CSV/PDF reports).

🏭 Robust Construction

- Frame: Heavy-duty steel structure with shock-absorbing base.

- Clamping System: Pneumatic grips for secure sample fixation (max 50 kg load).

- Safety: Emergency stop, protective cage, and anti-rebound mechanism.

Applications

✅ Consumer Electronics: Test smartphones, tablets, and wearables for screen/casing damage.

✅ Medical Devices: Validate surgical instruments, implants, and diagnostic equipment.

✅ Automotive Parts: Assess sensors, connectors, and fragile modules under assembly line drops.

✅ Packaging: Optimize cushioning design for glass, ceramics, and precision instruments.

✅ Military/Aerospace: Certify ruggedized equipment per MIL-STD-810 shock requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Max Payload | 50 kg (110 lbs) |

| Drop Height Range | 0–1200 mm (manual/auto adjustment) |

| Impact Surface | Steel plate with replaceable foam layers |

| Test Speed | Up to 60 drops/hour |

| Power Supply | 220V/50Hz or 110V/60Hz |

| Compliance | ISTA 1A, ASTM D5276, IEC 60068-2-31 |

Why Choose Our Zero Drop Tester?

✅ Precision Control: Servo-driven release eliminates human error in drop consistency.

✅ Adaptability: Test irregular shapes with modular fixtures (optional 6-axis robot arm).

✅ Cost-Effective: 50% faster cycle time vs. manual drop testing.

✅ Safety Certified: CE, UL, and ISO 13849-1 compliant safety interlocks.

✅ Global Support: 24/7 technical service with 3-year warranty.

Customer Success Stories

“Testing 0mm drops for microchips revealed packaging flaws our manual tests missed. A game-changer!”

– Semicon Solutions, Taiwan

“The G-force data helped us redesign medical device packaging to survive airport handling. ROI in 3 months!”

– MediSafe Technologies, USA

FAQ

Q: How does zero-height testing differ from standard drop tests?

A: Zero-height drops simulate instantaneous impacts (e.g., slipping from hands), while standard tests focus on higher falls.

Q: Can I test products with sharp edges or uneven surfaces?

A: Yes! Use our 3D-printed custom holders or vacuum fixture adapters.

Q: How often should calibration be performed?

A: We recommend annual calibration for the load cell and accelerometer. Kits are provided.

Q: Is the tester suitable for explosive/dangerous goods?

A: No. For hazardous materials, inquire about our ATEX-compliant explosion-proof models.

Upgrade Your Impact Testing Today!

📞 Request a Live Demo | 📧 Custom Quote in 24h | 🌍 Global Installation & Training

SEO Keywords:

- Zero drop tester

- Packaging impact test equipment

- ISTA 1A compliant drop tester

- Product durability testing machine

- Shock resistance tester