PRODUCT DETAILS

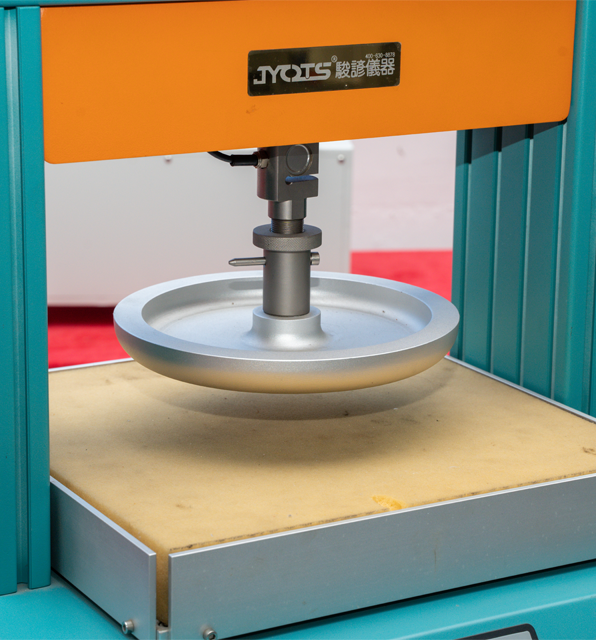

Sponge Compression Fatigue Testing Machine

Product Overview

The Sponge Compression Fatigue Testing Machine is an advanced testing system designed to evaluate the mechanical durability and long-term performance of sponge materials under cyclic compressive loads. It simulates real-world usage conditions, such as repeated compression in mattresses, automotive seating, furniture, or industrial applications. The machine provides precise measurements of deformation, load-bearing capacity, and fatigue resistance, enabling manufacturers to optimize material formulations, validate product quality, and predict service life.

Key Features

-

Versatile Testing Capabilities:

- Supports both constant force and constant displacement modes.

- Compatible with standard test methods (e.g., ASTM D3574, ISO 3385).

-

High Precision & Reliability:

- Equipped with calibrated load cells (accuracy ±0.5%) and linear encoders for accurate force/displacement measurement.

- Robust servo motor and hydraulic/pneumatic actuator for stable load application.

-

User-Friendly Interface:

- Touchscreen HMI with programmable test profiles and real-time data visualization.

- Data export options (CSV, Excel) and report generation.

-

Customizable Setup:

- Adjustable compression plates (size range: 50–200 mm diameter) to suit various sponge samples.

- Configurable test parameters (speed, force, stroke, cycles).

Technical Specifications

| Parameter | Details |

|---|---|

| Compression Force Range | 50–1000 N (adjustable via load cell calibration) |

| Compression Stroke | 0–200 mm (programmable) |

| Compression Speed | 1–200 mm/min (continuously variable) |

| Maximum Cycles | 1,000,000+ cycles (with built-in fatigue-resistant components) |

| Sample Dimensions | Up to 200 mm × 200 mm (thickness adaptable) |

| Control System | PLC-based automation with touch panel; supports custom test protocols |

| Data Acquisition Rate | 100 Hz (captures high-frequency deformation dynamics) |

| Power Requirement | 220V ±10%, 50/60 Hz, 5 kW |