PRODUCT DETAILS

Product Details

Impact-Related Parameters

-

Impact Energy: Typically simulated by converting the potential energy of a freely falling weight, which depends on the weight's mass and drop height. For example, the weight mass is 75 kg, with an adjustable drop height ranging from 10–300 mm.

-

Impact Frequency: Adjustable within a certain range, generally 1–120 times/min.

-

Impact Position: Usually located at specific positions on the treadmill running surface, such as at 66% of the length measured from the rear end.

Test Environment and Treadmill Operating Parameters

-

Treadmill Running Speed: Can simulate various running speeds, typically adjustable between 6–12 km/h.

-

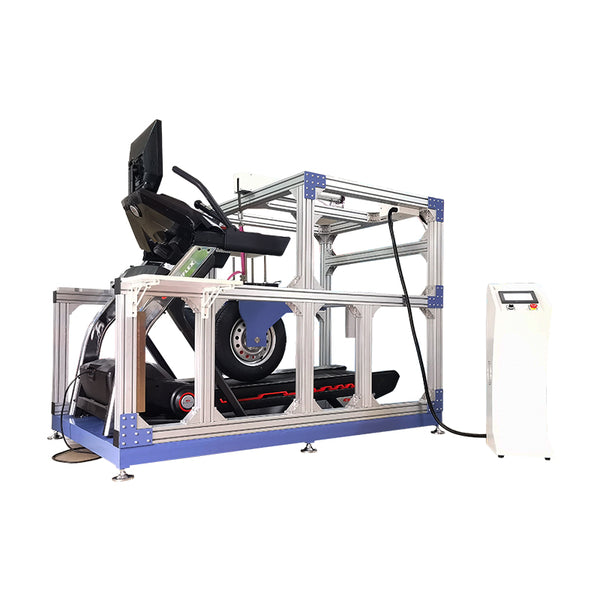

Testing Machine Base Dimensions: Generally large to ensure treadmill stability, such as 1200 mm × 2000 mm or 1500 mm × 1000 mm.

-

Effective Net Width of the Machine Platform: Typically around 100 cm.

Control and Display Parameters

-

Control Method: Typically uses PLC + color touchscreen control, with a programmable controller as the electrical control system. This setup is user-friendly and enables automated control.

-

Display Method: Commonly equipped with 5.7-inch or 7-inch TFT true color touchscreen displays, capable of showing real-time test parameters and status.

Other Parameters

-

Power Source: Generally provided by motor and compressed air, supplying the power needed for impact testing.

-

Safety Protection Devices: Includes emergency stop switches, overload protection devices, and other safety features to ensure a secure and reliable testing process.

-

Power Supply: Typically AC 220V 50Hz.