PRODUCT DETAILS

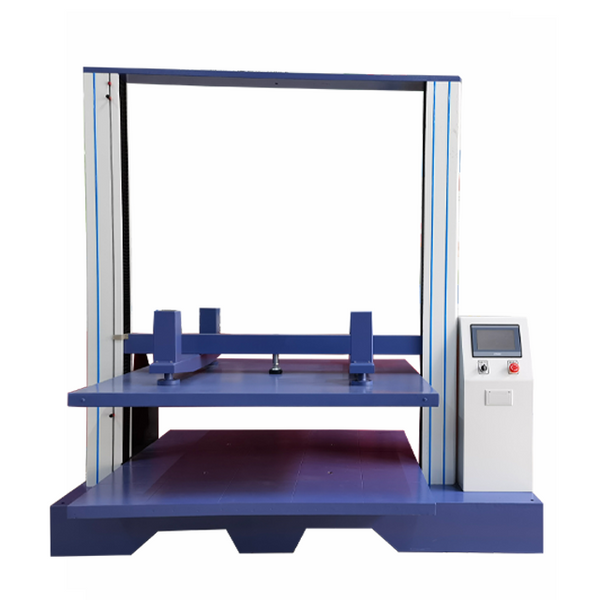

Carton Compression Tester – Optimize Box Strength & Stacking Safety

ASTM D642, ISO 12048 & ISTA 3A Compliant for Corrugated Boxes, Mailers & Displays

Our Carton Compression Tester simulates warehouse stacking and transport loads to validate box durability, edge crush strength (ECT), and long-term stacking safety – preventing costly product damage and logistics failures.

Core Testing Modes & Features

Dynamic Compression Simulation

- Constant Speed Compression: 1–500 mm/min to measure maximum load (BCT) and deformation.

- Creep Test: Hold load (e.g., 1 ton for 24 hrs) to simulate long-term stacking.

- Cycle Compression: Repeat loading/unloading (up to 10 Hz) for fatigue life analysis.

- Edge Crush Test (ECT): Measure flute strength with parallel plates ±0.1 mm precision.

Smart Automation

- Auto Align Plates: Laser-guided upper/lower plates ensure uniform pressure.

- Real-Time Monitoring: Track deformation via HD cameras and LVDT sensors.

- Batch Testing: Process 10+ boxes/hour with robotic conveyor (optional).

Multi-Standard Compliance

- Pre-Loaded Protocols: ASTM D642 (BCT), ISO 12048 (ECT), GB/T 4857.4 (stacking).

- Environmental Simulation: Test at -40°C to +80°C with humidity control (30–95% RH).

- Data Intelligence: Generate McKee formulas to predict box performance based on ECT.

Technical Specifications

| Parameter | Specification |

|---|---|

| Max Capacity | 15 kN (1500 kg / 3300 lbf) |

| Test Speed | 0.5–500 mm/min (BCT), 1–10 Hz (cyclic) |

| Plate Size | 800 × 800 mm (custom up to 1500×1500 mm) |

| Displacement Accuracy | ±0.1 mm |

| Compression Space | 1500 mm height (expandable) |

| Compliance | ISO 7500-1, CE, ISTA 3A, TAPPI T 804 |

Applications

✅ Corrugated Boxes: Validate BCT & ECT for retail packaging.

✅ Folding Cartons: Test rigidity of cosmetic/medical boxes.

✅ Logistics Packaging: Optimize pallet stacking for Amazon FBA/ISTA standards.

✅ Recycled Material: Assess strength loss after recycling cycles.

Why Choose Our Tester?

✅ All-in-One Platform: Run BCT, ECT, stacking, and vibration tests on one machine.

✅ Predictive Software: Auto-calculate required ECT for target stacking height.

✅ Multi-Box Fixture: Test 4 small boxes simultaneously (e.g., e-commerce mailers).

✅ Zero Calibration Drift: Self-correction load cells with NIST certification.

Customer Success Stories

“By integrating McKee formulas, we reduced box material usage by 18% without sacrificing stacking strength.”

– PackGreen Solutions, Germany

“Our compression test reports secured ISTA certification, cutting logistics damage claims by 32%.”

– Global Logistics Inc., USA

FAQ

Q: How to test irregular boxes (e.g., hexagons or cylinders)?

A: Use customizable fixtures (included) – 3D printable molds supported.

Q: Can it simulate wet storage conditions?

A: Yes – add humidity chamber (30–95% RH) to test damp box collapse.

Q: Is vibration testing possible?

A: Yes! Integrate ISTA 3A vibration module (optional) on same platform.

Q: What’s the cost per test?

A: <$0.30/test – energy-efficient design minimizes operational costs.

Request Custom Demo or Test Report!

📞 Technical Support | 📧 Download ASTM Standards | 🌍 Global Shipping in 3 Weeks

SEO Keywords:

- Carton compression tester

- Box compression test machine

- Edge crush tester (ECT)

- ASTM D642 compliance tester

- Packaging strength test equipment