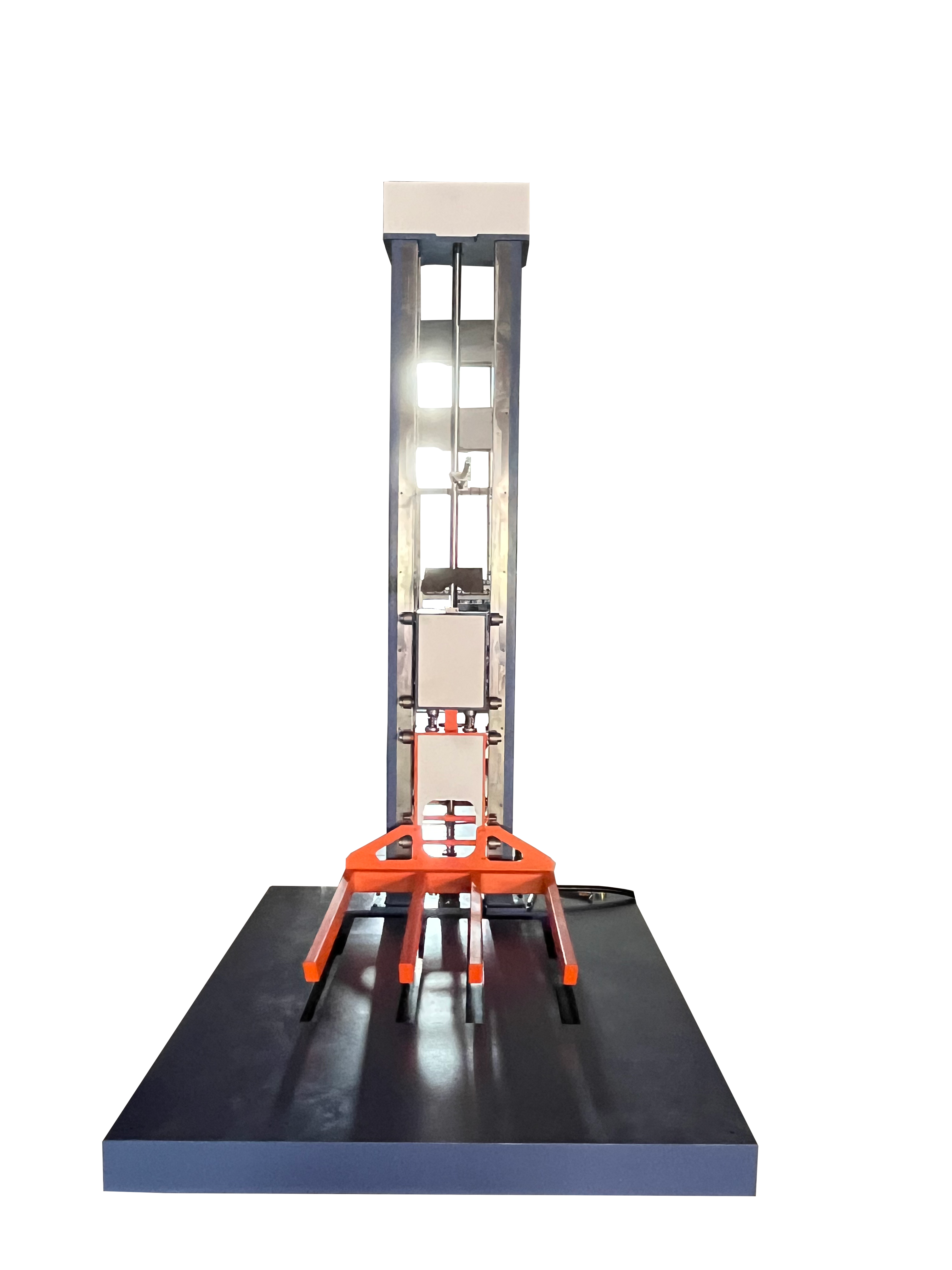

Junyan Zero drop test machine: A Tool Reshaping Packaging Testing Standards

In the context of increasingly complex logistics and transportation scenarios, the anti-drop performance of packaging directly determines the quality of product delivery. Junyan Zero drop test machine, with innovative technology at its core, provides enterprises with accurate and efficient packaging reliability testing solutions, and has become an important equipment for quality control in the manufacturing and logistics industries.

Cutting-edge Technology Drives Accurate Testing

Junyan Zero drop test machine integrates mechanical automation and intelligent control technology. It is equipped with a high-precision servo motor and cylinder collaborative drive system, which can ensure that the pallet moves downward at high speed and stably during the test, and accurately separates from the test piece. The equipment is equipped with a micron-level encoder, which can precisely control the drop height, which can be set arbitrarily from 20mm to 1500mm, with minimal error, ensuring the consistency of the height in each test. Through AI image recognition technology, it can capture the deformation data of the test piece in real-time during the drop process, providing a visual analysis basis for packaging optimization.

Industry-wide Application Practices

In the express logistics field, enterprises such as Yunda and Zhongtong often use Junyan testing machines to verify the reliability of various express packages. By simulating the drop conditions of faces, edges and corners that may occur during transportation, the damage degree of the packaging under different impacts is evaluated, so as to optimize the packaging design and reduce the damage rate of goods during transportation. For example, for fragile product packaging, after testing and improvement, the damage rate can be reduced by more than 42%.

In the electronics manufacturing industry, brands such as Huawei and Xiaomi use this equipment to complete the edge drop detection of mobile phone and tablet packaging, ensuring the complete delivery of products during transportation. Leading enterprises in the food industry verify the sealing performance and compressive strength of canned and bottled food packaging through testing machines, effectively avoiding leakage problems during transportation.

Standard Certification and Industry Value

The equipment strictly complies with international testing standards such as GB/T 4857 and ISTA, and has passed the ISO 9001 quality management system certification. According to 2024 market research, enterprises using Junyan Zero drop test machine have reduced average packaging costs by 18% and product return rates by 35%. With modular design and remote diagnosis function, the equipment can realize 7×24 hours continuous operation, significantly improving the detection efficiency of enterprises.

Choosing Junyan Zero drop test machine is not only choosing a set of precision testing equipment, but also building a full-chain quality assurance system for enterprises from R&D to delivery. In the wave of intelligent manufacturing upgrading, this equipment is helping enterprises improve product competitiveness and reshape the new benchmark of the packaging testing industry.