Office Chair Seat Impact Tester: The Key to Ensuring Office Chair Quality

- Posted by AdminMy Store

In the modern office environment, office chairs are essential tools that people use for long periods. Their quality is directly related to the comfort and safety of users. To ensure that office chairs can withstand various pressures and impacts during daily use, office chair seat impact testers play an indispensable role.

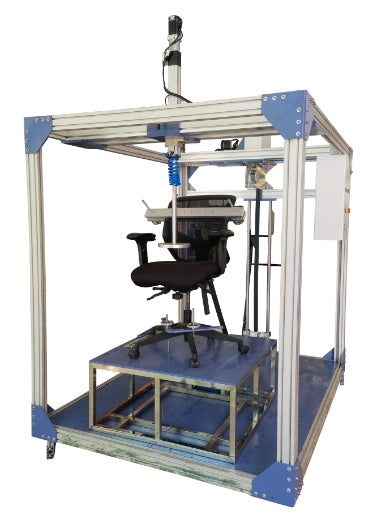

The office chair seat impact tester mainly simulates human movements and forces on the seat to evaluate the structural strength, stability, and durability of office chairs. A common testing method is the seat surface impact test. By dropping a heavy object of a certain mass from a specific height onto the seat surface of the office chair, the compressive capacity and deformation degree of the seat surface can be examined.

Its working system consists of three main parts: loading, measurement, and control. As the core, the loading system is responsible for generating and applying impact forces. It usually comprises heavy objects, lifting devices, and release mechanisms to achieve precise impact loading. For example, some testers use a standard sandbag with a diameter of 16 inches and a weight of 125 pounds, which is dropped from a height of 1 inch above the seat surface at a rate of 10 to 30 times per minute to impact the seat surface. The measurement system uses pressure sensors, displacement sensors, etc., to collect and record data such as the magnitude of the impact force, displacement, and deformation during the test. The control system coordinates the work of the loading and measurement systems, sets test parameters, controls the test process, and processes and analyzes the test data.

Regarding the test procedures that comply with international standards such as ANSI/BIFMA X5.1-2017, when conducting the Front Corner Load-Ease Test-Cyclic, a front corner loading device that meets the standard material size requirements should be used. A vertical force of 890N (200lbf) is applied at a speed of 10 - 30 times per minute, and the test is conducted 20,000 times for each of the two front corners respectively. In the Arm Durability Test-Cyclic, the loading device also needs to meet the standards. A downward force of 400N (90lbf) is applied at an angle of 10° ± 1° at a speed of 10 - 30 times per minute, and the test is carried out 60,000 times.

The application of office chair seat impact testers helps manufacturers improve product quality, identify problems in design and material selection in advance, optimize product performance, and ensure that office chairs can withstand various impacts during long-term use and maintain good working conditions. This provides office workers with a safe and comfortable office experience and promotes the development of the office chair industry towards higher quality.

Categories

- Office Chair Furniture Testing Equipment

- Environmental series test equipment

- Mobile phone and notebook series testing

- Wire material testing series

- Sports Equipment Testing Equipment

- Luggage

- Bicycle Scooter Baby Stroller

- Tensile testing machine

- Constant temperature and humidity test chamber

- Thermal shock test chamber

- Salt spray test chamber

- UV aging test chamber

Recent Posts