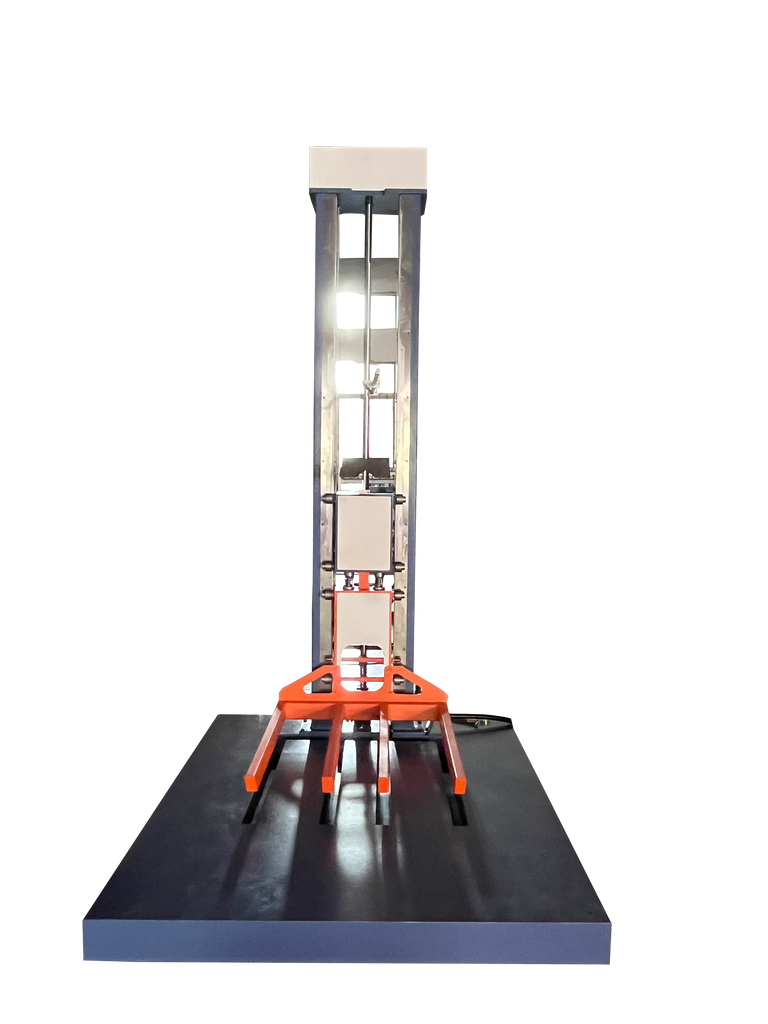

Junyan Zero drop test machine: A Tool Reshaping Packaging Testing Standards

In the context of increasingly complex logistics and transportation scenarios, the anti-drop performance of packaging directly determines the quality of product delivery. Junyan Zero drop test machine, with innovative technology at its core, provides enterprises with accurate and efficient packaging reliability testing solutions, and has become an important equipment for quality control in the manufacturing and logistics industries. Cutting-edge Technology Drives Accurate Testing Junyan Zero drop test machine integrates mechanical...

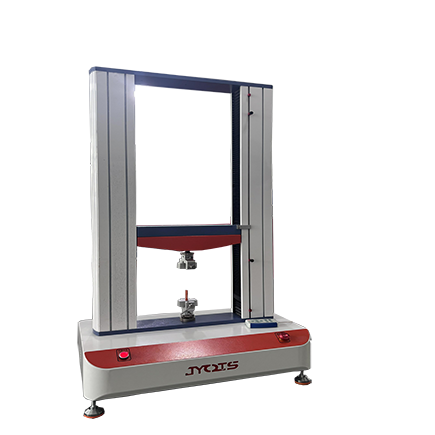

Double-Column Universal Material Testing Machine: The Core Equipment for High-Precision Mechanical Property Testing

In the field of materials science and engineering, the double-column universal material testing machine is a key device for achieving precise detection of material mechanical properties. With its unique structural design, intelligent control system, and wide range of application scenarios, it has become the preferred tool for quality control in manufacturing and research and development testing in scientific research institutions. This article will analyze the technical charm of this high-performance...

High and Low Temperature Test Chambers: A Powerful Tool for Harsh Environment Simulation

In numerous fields such as material research and development, and electronic product manufacturing, high and low temperature test chambers are indispensable testing equipment. They accurately simulate extreme temperature environments, providing crucial data support for product reliability testing. The core advantage of high and low temperature test chambers lies in their powerful temperature control capabilities. Generally, their temperature range can reach as low as -70°C and as high as 150°C. Some...

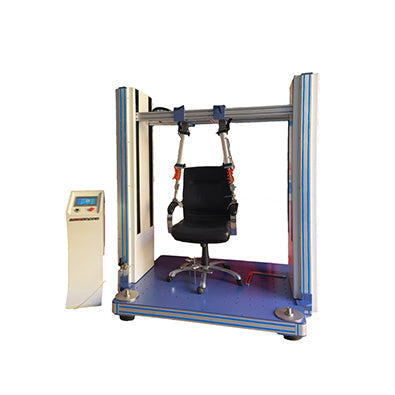

Office Chair Armrest Strength Tester: Revolutionizing Testing Standards and Empowering Quality Upgrades

In the quality control of the office furniture industry, the office chair armrest strength tester has become a crucial tool. With the integration of new technologies, it is constantly revolutionizing testing standards and empowering quality upgrades in the industry. In recent years, the new Office chair armrest strength testing machine developed by [X] Technology Company has attracted much attention. This device is equipped with advanced sensor technology and intelligent control...

Unveiling the Tensile Strength Tester: The Core Tool for Material Performance Evaluation

In the fields of materials science and industrial production, the tensile strength tester stands as a core device for assessing the mechanical properties of materials. This sophisticated instrument can accurately measure the maximum stress that a material can withstand under tensile loading until fracture, providing crucial data support for product quality control and the research and development of new materials. The working principle of the tensile strength tester is based...

Tensile Strength Testing Machine: A Key Device for Material Property Testing

In the process of material research and development as well as quality control, the tensile strength testing machine serves as a core device for accurately measuring the mechanical properties of materials. By simulating the stretching process, it provides reliable testing data for industries such as metals, plastics, and rubber, acting as a "quality gatekeeper" in industrial production. The tensile strength testing machine operates based on Hooke's Law and sensing technology....

The Role of Office Chair Seat Impact Testing Machines in the R&D and Design Phase

In the research, development, and design phase of office chairs, seat impact testing machines serve as core "assistants" in transforming concepts into market-ready products. By scientifically simulating real-life usage scenarios, these machines provide crucial data support to designers, ensuring that products meet both safety and comfort standards. During the design verification stage, once the R&D team completes the initial design and produces prototypes, seat impact testing machines are employed to...

Electronic Tensile Testing Machine: The Key "Guardian" of Material Performance Testing

In the field of materials science and engineering, the electronic tensile testing machine is a well-deserved "unsung hero". It converts the force value generated when the material is stretched into an electrical signal through a sensor, and then processes it through a data acquisition system to accurately present key mechanical performance parameters of the material, such as tensile strength and yield strength, laying a solid foundation for material research and...